SILICA REFRACTORIES FOR ELECTRIC-STEELMAKING FURNACES ACCORDING TO DSTU 2343-94 (GOST 1566-96)

ED-1

Silica refractories of this grade are used for electric-steelmaking furnace arches laying. However, subject to agreement with the customer, it is possible to use ED grade refractories for other heat aggregates.Depending on chemical composition and application, silica products of this type are divided into ED and ED-1.

ED-1 grade silica products with SiO weight content of not less than 95% are used in electric-steelmaking furnaces with capacity less than 50t.

The products are supplied on wooden pallets interlaid with cardboard, with protected corners, wrapped with stretch film and bundled with plastic strip.

| Parameter description | Value |

|---|---|

| Type | siliciferous |

| Group | silica (SiO2 > 93%) |

| Refractoriness value | fire resistance (1580 to 1770°С) |

| Porosity degree | average dense (Ptot 20-30%) |

| Heat treatment method | burnt |

| Molding process | semidry forming |

| Binding type 1 | with inorganic binders |

| Binding type 2 | ceramic |

| Intended purpose | repair/construction |

| scope of application | in electric-steelmaking furnaces with the capacity of up to 50 t |

| Reference document for product properties | Silica refractories for electric-steelmaking furnaces according to DSTU 2343-94 (GOST 1566-96) |

| Reference documents for product dimensions | Silica refractories for electric-steelmaking furnaces according to DSTU 2343-94 (GOST 1566-96) |

| Parameter description | Value |

|---|---|

| Al2O3, % | ≤1,5 |

| CaO, % | ≤2,2 |

| Compression ultimate strength, N/mm2, not less than | 25 |

| Density, g/сm3 | 2,32-2,36 |

| Fire resistance, °С, not less than | 1700 |

| Fusion point, °С, not less than | 1650 |

| Interconnected porosity, %, not more than | 22 |

| SiO2, % | ≥95 |

| Form | Article No. | Additional information | Photo |

|---|---|---|---|

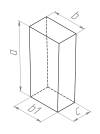

| crossover double-sided feather-edged brick | No.7 | for lining of sector arch rows with thickness 230mm in combination with straight product No.2 | |

| No.8 | for lining of sector arch rows with thickness 300mm in combination with straight products No.3 and 4 | ||

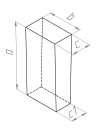

| front double-sided feather-edged brick | No.5 | for lining of interelectrode arches and arches with thickness 230mm in combination with straight product No.2 and for lining of arch sector rows in combination with feather-edge product No.9 | |

| No.6 | for lining of interelectrode arches and arches with thickness 300mm in combination with straight product No.3 and for lining of arch sector rows in combination with feather-edge product No.10 | ||

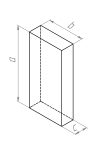

| straight brick | No.1 | for interlock selection | |

| No.2 | for lining of arch rows with thickness 230mm in combination with feather-edge products No.5 and 7 | ||

| No.3 | for lining of arch rows with thickness 300mm in combination with feather-edge products No.6 and 8 | ||

| depending on drawing | customer drawing | UNDEF | |

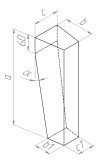

| pyramidal sided feather-edged brick | No.10 | for lining of sector arch rows with thickness 300mm in combination with feather-edge product No.6 | |

| No.9 | for lining of sector arch rows with thickness 230mm in combination with feather-edge product No.5 | ||

| electrode brick | No.11 | for lining of rings of electrode holes with diameter 270mm and in combination with product No.12 for holes diameter 305-440mm in arches with thickness 230mm | |

| No.12 | for lining of rings of electrode holes with diameter 475mm and in combination with product No.11 for holes diameter 305-440mm in arches with thickness 230mm | ||

| No.13 | for lining of internal half rings of electrode holes with diameter 420mm and in combination with product No.14 for holes diameter 450-600mm in arches with thickness 300mm | ||

| No.14 | for lining of internal half rings of electrode holes with diameter 630mm and in combination with product No.13 for holes diameter 450-600mm in arches with thickness 300mm | ||

| external electrode brick | No.15 | for lining of external half rings of electrode holes with diameter 420 and in combination with product No.16 for holes diameter 450-600 in arches with thickness 300 | |

| No.16 | for lining of external half rings of electrode holes with diameter 630 and in combination with product No.15 for holes diameter 450-600 in arches with thickness 300 | ||

| back brick | No.17 | for lining of arch support with thickness 230mm | |

| No.18 | for lining of arch support with thickness 300 | ||

| bar | No.4 | for lining of arch rows with thickness 300 in combination with straight product No.3 and feather-edge brick No.8 |