CHAMOTTE AND SEMIACID REFRACTORY PRODUCTS OF GENERAL PURPOSE ACCORDING TO GOST 390-96

SHA

Chamotte alumino-silicate refractories of SHA grade are used due to their properties (resistance to temperature drops, impact of acids and alkalies) in various industry sectors.High chemical and physical characteristics are conditional upon, first of all, quality of the used at production raw material. For chamotte brick production there are used qualitative components: chamotte powder and grinded fore resistant clay that undergo high temperature burning in the process of mixing.

The shapes and dimensions of the SHA-1 grade products differ due to multifunctional application.

The presented SHA grade products have maximal temperature of application 1250-1400°С.

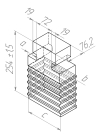

The products are delivered on wooden pallets, laid with cardboard, protected with angles, wrapped with stretch-film and bundled with polypropylene or polyester strip.

| Parameter description | Value |

|---|---|

| Type | aluminosilicate |

| Group | chamotte (Al2O3 28-45%) |

| Refractoriness value | fire resistance (1580 to 1770°С) |

| Porosity degree | average dense (Ptot 20-30%) |

| Heat treatment method | burnt |

| Molding process | semidry forming |

| Binding type 1 | with inorganic binders |

| Binding type 2 | ceramic |

| Intended purpose | repair/construction |

| scope of application | products of general purpose for laying of various heat aggregates |

| Reference document for product properties | Chamotte and semiacid refractory products of general purpose according to GOST 390-96 |

| Reference documents for product dimensions | Refractories of general purpose according to DSTU GOST 8691:2009 (ISO 5019-1-84) (with amendments No.1,2,3,4) |

| Parameter description | Value |

|---|---|

| Al2O3, % | ≥30 |

| Compression ultimate strength, N/mm2, not less than | 20 |

| Fire resistance, °С, not less than | 1690 |

| Fusion point, °С, not less than | 1300 |

| Interconnected porosity, %, not more than | 24 |

| Form | Article No. | Additional information | Photo |

|---|---|---|---|

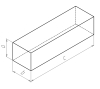

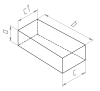

| bar | No.97 | ||

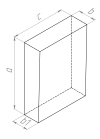

| extension hearth bottom side brick | No.92 | ||

| No.93 | |||

| edge feather-edged brick (double-sided or one-sided) | No.42 | ||

| No.43 | |||

| No.44 | |||

| No.45 | |||

| No.46 | |||

| No.47 | |||

| No.48 | |||

| front feather-edged brick (double-sided or one-sided) | No.20 | ||

| No.21 | |||

| No.22 | |||

| No.23 | |||

| No.24 | |||

| No.25 | |||

| No.26 | |||

| No.27 | |||

| No.28 | |||

| No.29 | |||

| No.30 | |||

| No.31 | |||

| No.32 | |||

| suspended brick | No.110 | ||

| No.79 | |||

| No.80 | |||

| No.81 | |||

| No.86 | |||

| No.87 | |||

| No.88 | |||

| No.89 | |||

| No.90 | |||

| No.91 | |||

| straight brick | No.1 |  | |

| No.10 | |||

| No.2 | |||

| No.3 | |||

| No.4 | |||

| No.5 | |||

| No.5 quartz-chamotte | Interconnected porosity not more than 26%. (produced according to the requirements of the customer) | ||

| No.6 | |||

| No.7 | |||

| No.8 | |||

| No.9 | |||

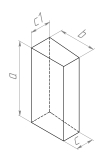

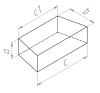

| one-and-a-half straight brick | No.11 | ||

| No.12 | |||

| No.13 | |||

| No.14 | |||

| No.15 | |||

| three-quarter straight brick | No.16 | ||

| No.17 | |||

| No.18 | |||

| No.19 | |||

| skew brick | No.60 | ||

| No.61 | |||

| No.62 | |||

| No.63 | |||

| No.64 | |||

| No.65 | |||

| No.66 | |||

| No.67 | |||

| No.68 | |||

| No.69 | |||

| No.70 | |||

| No.71 | |||

| No.72 | |||

| No.73 | |||

| suspended-roof brick | No.111 | ||

| No.82 | |||

| No.83 | |||

| No.84 | |||

| No.85 | |||

| keyed suspended-roof brick | No.76 | ||

| No.77 | |||

| No.78 | |||

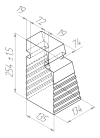

| trapezoidal brick (double-sided and one-sided) | No.49 | ||

| No.50 | |||

| No.51 | |||

| No.52 | |||

| No.53 | |||

| No.54 | |||

| cross trapezoidal brick (double-sided ) | No.55 | ||

| No.56 | |||

| No.57 | |||

| No.58 | |||

| No.59 | |||

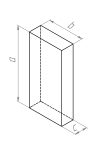

| plate | No.94 | ||

| No.95 | |||

| No.96 | |||

| front one-and-a-half feather-edged brick (double-sided and one-sided) | No.33 | ||

| No.34 | |||

| No.35 | |||

| No.36 | |||

| No.37 | |||

| No.38 | |||

| No.39 | |||

| No.40 | |||

| No.41 | |||

| window brick | No.74 | ||

| No.75 | |||

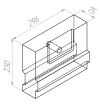

| burner brick | No.100 | ||

| No.101 | |||

| No.102 | |||

| No.98 | |||

| No.99 | |||

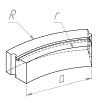

| arch brick | No.103 | ||

| No.104 | |||

| No.105 | |||

| No.106 | |||

| No.107 | |||

| No.108 | |||

| No.109 | |||

| customer drawing |