REFRACTORIES FOR SYPHON STEEL TEEMING ACCORDING TO DSTU GOST 11586:2006

SHS-28

Chamotte refractories of SHS-28 grade are used for steel pouring with the help of syphon method into casting-form and moulds, intermediate funnels with nozzles - for top casting.For the products of soft-mud method of production there is acceptable the interconnected porosity of not more than 28%. Subject to the parties agreement there are allowable the following standards: fire resistance - not less than 1650°С, residual variation of dimension at heating - not more than 1.0%.

SHS-28 No.41 (rectangular four-way collar star) and nozzles (SHS-28 No.No.88, 89, 92) intended for export are wrapped into cardboard or paper, wrapped with stretch-film and laid into wooden case with laid along the perimeter cardboard. The layers are laid with cardboard or liner, and the gaps between the products, from case walls and under the cover are filled with wood chips or flakes.

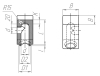

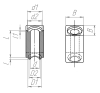

Siphon tubes (SHS-28 No.No.69-71, 74-77, 82-86) and nozzles (SHS-28 No.No.88, 89, 92) are laid on wooden pallet, interlaid with cardboard sheets, wrapped with stretch film and bundled with polypropylene (or polyester) strip.

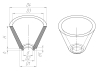

Funnels (SHS-28 No.No.1, 3, 4) are laid on wooden pallet, interlaid with cardboard sheets, wrapped with stretch film, covered with wooden cover and bundled with polypropylene (or polyester) strip.

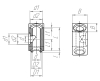

Rising pipes (SHS-28 No.No.6-10) and stars (SHS-28 No.No.31, 33, 35, 36, 41) are laid on wooden pallet, interlaid with cardboard sheets, protected with angles along the perimeter, wrapped with stretch film and bundled with polypropylene (or polyester) strip.

| Parameter description | Value |

|---|---|

| Type | aluminosilicate |

| Group | chamotte (Al2O3 28-45%) |

| Refractoriness value | fire resistance (1580 to 1770°С) |

| Porosity degree | average dense (Ptot 20-30%) |

| Heat treatment method | burnt |

| Molding process | semidry/soft mud |

| Binding type 1 | with inorganic binders |

| Binding type 2 | ceramic |

| Intended purpose | technology |

| scope of application | for steel pouring with the help of syphon method into casting-form and moulds, intermediate funnels with nozzles - for top casting |

| Reference document for product properties | Refractories for syphon steel teeming according to DSTU GOST 11586:2006 |

| Reference documents for product dimensions | Refractories for syphon steel teeming according to DSTU GOST 11586:2006 |

| Parameter description | Value |

|---|---|

| Al2O3, % | ≥ 28 |

| Fire resistance, °С, not less than | 1670 |

| Interconnected porosity, %, not more than | 15-26 |

| Residual variation of dimension at heating, %, not more than, at temperature | 0,5 (1350 °С) |

| Thermal resistance, thermal cycles |

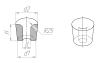

| Form | Article No. | Additional information | Photo |

|---|---|---|---|

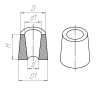

| funnel | No.1 | ||

| No.3 | |||

| No.4 | |||

| end syphon tube | No.84 (L 150mm, d 40mm) | ||

| No.84 (L 200mm, d 40mm) | |||

| No.84 (L 250mm, d 40mm) | |||

| No.84 (L 300mm, d 40mm) | |||

| No.85 (L 150mm) | |||

| No.85 (L 200mm) | |||

| No.85 (L 250mm) | |||

| No.85 (L 300mm) | |||

| No.86 (L 150mm) | |||

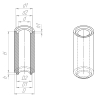

| through syphon tube | No.69 (L 150mm) |  | |

| No.69 (L 200mm) | |||

| No.69 (L 250mm) | |||

| No.69 (L 300mm) | |||

| No.70 (L 150mm) | |||

| No.70 (L 200mm) | |||

| No.70 (L 250mm) | |||

| No.70 (L 300mm) | |||

| No.71 (L 200mm) | |||

| No.71 (L 300mm) | |||

| No.75 (L 300mm, d 40mm) | |||

| No.76 (L 150mm) | |||

| through syphon tube with side hole | No.75 (L 200mm, d 40mm) | ||

| No.76 (L 200mm) | |||

| No.76 (L 250mm) | |||

| No.76 (L 300mm) | |||

| No.77 (L 150mm) | |||

| rectangular four-way star with slot | No.31 (d 40mm) | ||

| No.33 | |||

| No.35 | |||

| No.36 | |||

| nozzle for casting-form | No.88 (d 50mm) | ||

| No.89 | |||

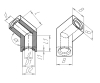

| angle syphon tube | No.82 | ||

| No.83 (135 deg.) | |||

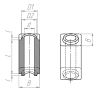

| rising pipe | No.10 (Н 250mm, d 100mm) |  | |

| No.10 (Н 250mm, d 120mm) | |||

| No.10 (Н 300mm, d 100mm) | |||

| No.10 (Н 300mm, d 120mm) | |||

| No.6 (Н 300mm) | |||

| No.7 (Н 300mm) | |||

| No.8 (H 300mm) | |||

| No.9 (H 300mm) | |||

| rectangular four-way star с shaft collar | No.41 | ||

| through syphon tube with two shaft collars | No.74 (L 200mm) | ||

| nozzle for intermediate funnels | No.92 (d 50mm) | ||

| customer drawing |